Dynamic Process Group resizes, or cores various types of wafers, including silicon wafers, up to 12″, or 300mm in diameter into smaller wafers. We core all standard sized wafers; 2″, 3″, 4″, 6″, 8″, and 12″. Patterned and blank wafers can be cut to any geometry or size; round, square, notched, flat on the bottom, multiple flats, etc.

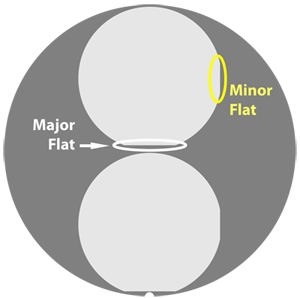

A 200mm silicon wafer that has been cut into two 100mm wafers with multiple wafer flats. The major wafer flats have been aligned to the original wafer’s notch.

We core silicon, germanium, gallium arsenide, indium phosphide, graphite, silicon carbide, diamond coated wafers, stainless steel wafers, and many others.

DPG’s Resizing and Wafer Processing Details:

- A blanket coat of photoresist is applied for wafer protection

- The wafers are background to the required thickness

- A custom program is created based on customer requirements

- Synova Microjet technology is used to process the wafers

- The resized wafers are edge rounded to increase their ability to handle mechanical stress

- A detailed inspection is performed

- The processed wafers are stripped of the photoresist layer and cleaned in a class 100 clean room environment

- The wafers are packaged and shipped